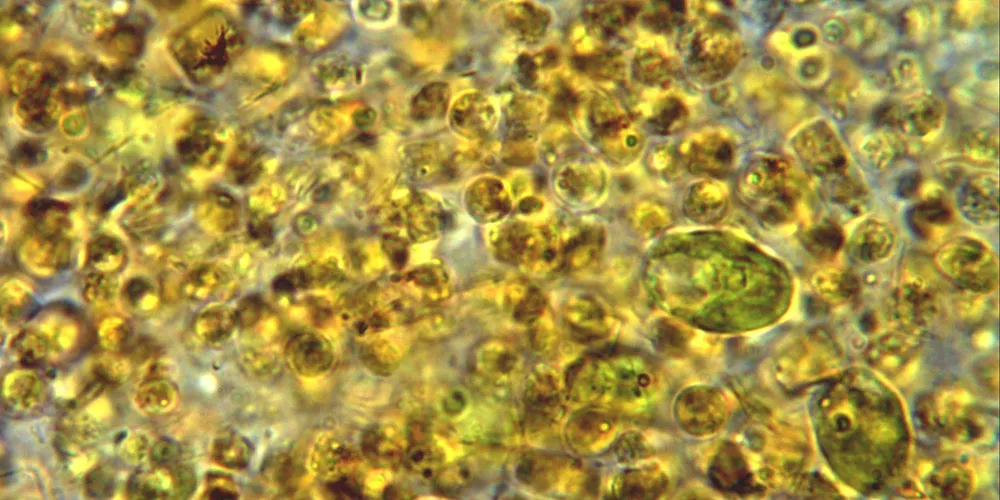

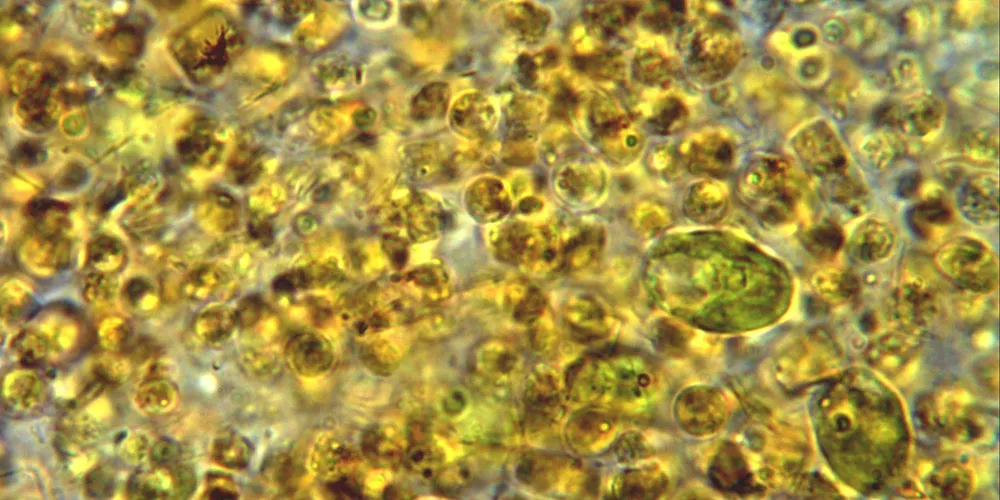

ALGAE WEEK BROUGHT TO YOU BY REED MARICULTURE: Shellfish growers face feed bottlenecks — it all begins with algae

In the first of a series of five articles, Reed Mariculture introduces us to the challenges of shellfish nutrition.

In the first of a series of five articles, Reed Mariculture introduces us to the challenges of shellfish nutrition.